The People of Pitco Featuring Karen Derie

At Pitco, every team member brings unique skills and dedication that make a difference on the shop floor and beyond. Karen Derie, our Health and Safety Manager, has been part of the Pitco team for three years and draws on more than 35 years of manufacturing experience across the military, aerospace, and pharmaceutical industries.

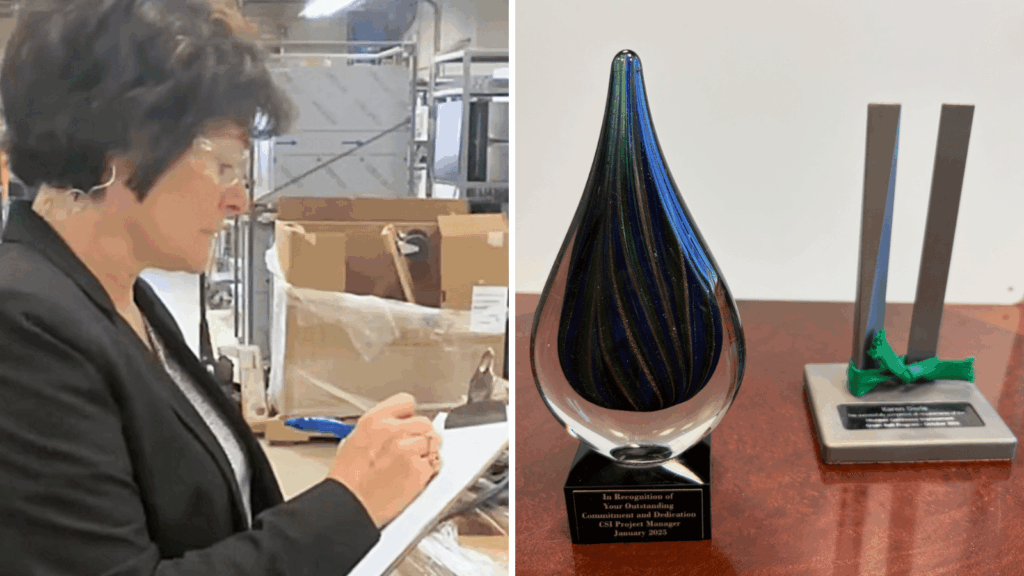

Since joining us, she’s led continuous improvement efforts, guided a successful ERP launch, and now focuses on keeping our workplace safe, productive, and centered on the people who power our success. We sat down with Karen to learn a little more about her.

Can you tell us a little about your role at Pitco?

I was hired as Continuous Improvement Manager. In that role, I used Kaizen processes to improve production on the shop floor and trained staff in various lean disciplines. During that time, we were implementing a new ERP system, and the need arose for a new project leader, so I was given that project. We had a successful launch at the beginning of this year.

Then Pitco saw a need for a Health and Safety Manager. In my past manufacturing roles I’ve always held a position on safety committees so it was a good fit.

Have you noticed any differences between our manufacturing processes (kitchen equipment) and the different things that you’ve done in your background before?

There are still many of the same standards. I have a strong background in ISO-based systems and processes. The standard of work is the same for best manufacturing practices.

Why is safety so important in the manufacturing world?

Safety is always first. Our employees are our most important resource. I always have the heart of the operator in mind, and I love working with people. My goal is always to be compliant and to have happy employees.

We do have a safety committee that I jumped into when I was hired initially three years ago. That’s now a robust and thriving program, which involves not only management and supervision but also shop floor employees. We meet once a month and conduct internal audits of all the different departments, and then we give feedback to management and the operations team to make improvements.

What are some ways to keep safety compliance up?

Educating staff to keep safety at the forefront is key. You need to be involved in safety at all levels to drive compliance. The Five S’s (Sweep, Sort, Standardize, Set in place, and Sustain) and visual factory are foundational to safety and quality.

What do you like most about your job?

The people. I get my energy from people. I’m a very social being, and I like working in positions where I get to work with others.

What kinds of activities do you like to do outside of work?

I’m on the board of directors in my community garden club. The work we do beautifies my community, and we also make donations to different local charities. It’s a nice way to give back.

Thanks so much, Karen, for chatting with us and helping our teams to stay safe!

Topics

- Foods & Trends (92)

- Fryers (90)

- Oil (58)

- Fried Food (53)

- Filtration (32)

- See All Topics