Fighting Rising Commercial Oil Prices with Smarter Filtration

Oil is eating into profits faster than ever. With inflation, tariffs, and global supply disruptions driving up costs, restaurants can’t afford to waste a drop. Rising commercial oil prices aren’t just a headline. They’re a daily threat to the bottom line.

The good news? Filtration is one of the most effective ways to make every batch last longer without sacrificing food quality. With the right oil management strategy, operators can cut costs, maintain consistency, and streamline back-of-house operations across commercial kitchens worldwide.

Why Rising Oil Prices Are Hurting Restaurant Profit Margins

Cooking oil isn’t just more expensive. It’s unpredictably volatile. From global economic shifts to proposed tariffs in the United States on imported vegetable oils, the price of cooking oil is rising across the board. For restaurants that rely on large volumes of fryer oil, the impact is immediate and ongoing.

Even more impactful is how often oil is discarded due to poor maintenance or skipped filtering. Wasted oil means wasted money, and as commercial oil prices continue to climb, that waste becomes harder to ignore. Without a solid oil management plan, kitchens lose profit with every unnecessary change-out.

How Oil Filtration Keeps Food Quality High and Costs Low

Over time, oil breaks down. High heat, food particles, and repeated use speeds up this process. The result? Food that looks and tastes off, is greasy, unevenly cooked, or dark in color.

Filtration removes impurities that degrade oil quality. Cleaner frying oil means better food and fewer change-outs. It keeps flavor and appearance consistent, protecting both the product and the brand. It’s a simple but powerful way to control costs without compromising the customer experience.

Smarter Frying with Built-In Filtration from Pitco

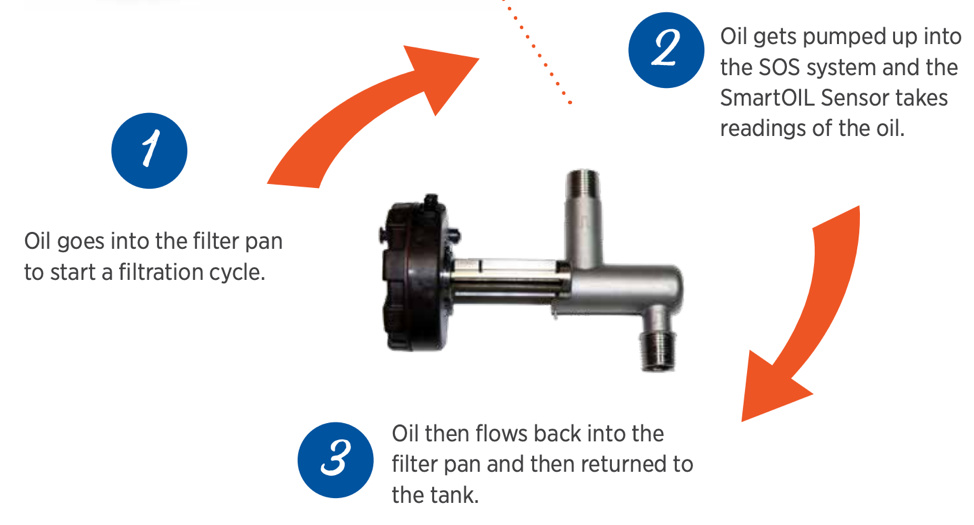

Manual filtering takes time, creates safety risks, and often falls to the bottom of the to-do list. With built-in filtration systems on Pitco fryers, operators can clean oil quickly and efficiently, often at the push of a button.

These systems reduce downtime, improve safety, and eliminate guesswork. With fewer steps and easier controls, regular filtration becomes a routine part of operations, and staff stays focused on food, not maintenance.

The Long-Term ROI of Investing in Oil Filtration

Operators often focus on the upfront fryer cost without considering what they’ll save in oil over time. Oil filtration systems are one of the fastest ways to cut recurring expenses. Using less oil means buying less oil, which adds up month after month.

There’s more to gain than just oil savings. Filtration helps extend equipment life, reduce labor, improve safety, and ensure food stays consistent across shifts. For multi-unit operators or high-volume kitchens, the savings multiply.

By supporting consistency, efficiency, and smart oil management in every kitchen, Pitco fryers and filtration systems are built to grow with your operation, no matter the size.

Rising commercial oil prices aren’t going away. But how your kitchen handles that challenge can make all the difference. With Pitco filtration technology, operators can reduce waste, protect margins, and improve food quality with every batch.

Topics

- Foods & Trends (91)

- Fryers (88)

- Oil (58)

- Fried Food (52)

- Filtration (32)

- See All Topics